SPS Internships

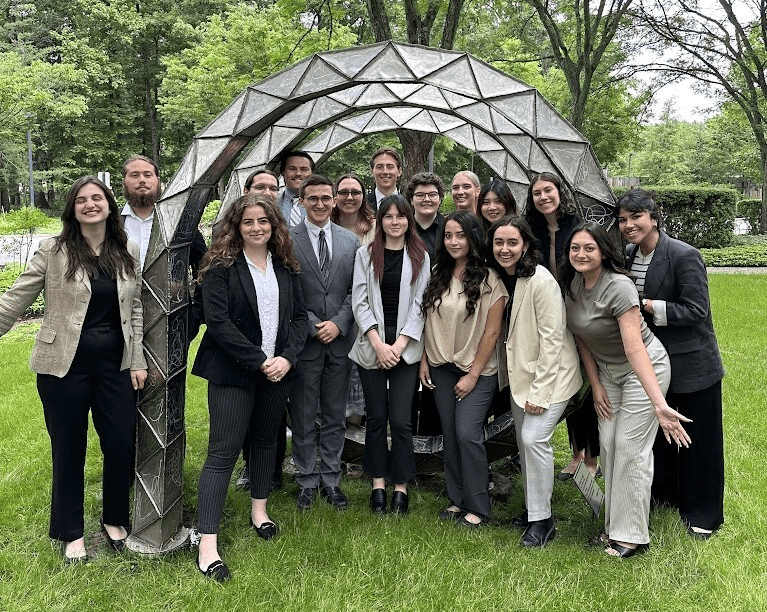

Meet the 2023 SPS Interns

Broaden Your Education... Diversify Your Interests... Advance Your Career!

Through the SPS summer internship program, physics undergraduates are placed in organizations that utilize their knowledge, experience and energy to advance meaningful assignments relevant to the organization and the advancement of physics more generally. Participating organizations assign one or more mentors from their senior staff to guide each intern’s work and overall experience. The SPS national office administers the program, hosts joint orientation and concluding sessions, and holds many group activities throughout the summer. For more information, see SPS Internship Program Details.

The cohort of SPS summer interns share their varied experiences with each other, live in housing in the heart of Washington, DC, and participate in a number of engaging supplemental activities throughout the summer.